Despite the fact that the Boeing 747 jumbo jet is no longer in production, it remains the most popular outsized cargo mover in the world of air freight. One of the primary reasons why it is such a useful airframe for the world’s biggest cargo flyers is its nose door, which allows the loading of pallets, vehicles, equipment, and anything else that would never be possible to put in through a side door.

The ![]() Boeing 747 was originally designed with the nose door as an intended feature because it was expected to be a very popular cargo aircraft from conception. When the production line was finally shuttered in 2023, the last examples that rolled out the doors were cargo variants for Atlas Air, the largest 747 operator in the world. The replacement for the 747 freighter will not feature a nose door; it remains to be seen how the industry will adapt with the new 777-8F and A350F Next-Gen freighters.

Boeing 747 was originally designed with the nose door as an intended feature because it was expected to be a very popular cargo aircraft from conception. When the production line was finally shuttered in 2023, the last examples that rolled out the doors were cargo variants for Atlas Air, the largest 747 operator in the world. The replacement for the 747 freighter will not feature a nose door; it remains to be seen how the industry will adapt with the new 777-8F and A350F Next-Gen freighters.

The Do-It-All Cargo Jet

The 747’s basic configuration was derived from Boeing’s entry into the US Air Force Heavy Logistics System (CX-HLS) competition, where a front-loading capability was a key requirement for transporting large military equipment like tanks. Thanks to that military-grade design, the 747 is one of the most efficient and heavy-duty cargo planes in the world.

The nose door allows for the straight-in loading of items up to 185 feet (56.4 meters) long. That means that a 747 can load in aircraft wings, massive pipes for industrial gas and oil projects, or even construction cranes. This is crucial when items are too long to pivot around the door frame of a side door, as found on most other cargo aircraft. Not only are long items much more easily moved with the 747’s nose door, but it can also load wider pallets, up to 12.5 feet (3.8 meters) wide, than competing cargo jets.

While many 747s were later converted from passenger to cargo use, these Boeing Converted Freighters (BCFs) typically lack the nose door because retrofitting it is prohibitively expensive. Consequently, factory-built freighters (like the 747-400F and 747-8F) remain highly sought after for specialized missions. Operators can even load or unload through the nose and side doors simultaneously, significantly reducing turnaround times at airports.

Boeing’s Master Plan

The iconic hump on all 747s, or the upper deck, is a design feature that is derivative of its intended purpose as a cargo freighter. To allow for a hinged nose door that could ‘swallow’ large freight, the cockpit had to be moved out of the way. By raising the cockpit, the entire length of the main deck became available for cargo. The space behind the cockpit was initially a byproduct of aerodynamic fairing.

In the 1960s, Boeing engineers anticipated that supersonic jets would take over passenger travel, leaving the 747 to serve primarily as a freighter. Since the company expected to be converting passenger 747s to cargo freighters on a large scale at some point in the future, every single variant of the 747 was made using the same hump upper deck fuselage design. The extra space was later famously utilized as a first-class lounge by airlines like Pan Am.

When it debuted in 1969, the 747 was nearly two and a half times bigger than the largest existing passenger jet to precede it, Boeing’s own 707. Because it could carry 400-600 passengers, airlines could slash ticket prices. The 747 earned its regal nickname, ‘Queen of the Skies,’ because it was the first aircraft to truly democratize global travel through its unprecedented scale, which was complemented by extraordinary luxury in the unique upper deck spaces.

Boeing was very confident in the Golden Age of the jet era that supersonic transports (SSTs), like the Concorde and Boeing’s ultimately failed 2707 project, meant that the 747 would have a short career before it was obsolete. Boeing anticipated that once SSTs dominated the passenger market, the 747 would need a ‘second life’ as a freighter to remain economically viable. The fuselage width was specifically designed to fit two standard 8×8-foot shipping containers side-by-side.

Military Grade Engineering

While the 747 was an entirely original design and not a direct conversion of the military bid, it incorporated critical technologies developed for the CX-HLS. In 1964, the US Air Force launched a competition to find a massive strategic transport. Boeing’s high-wing, four-engine proposal lost the competition to the Lockheed C-5 Galaxy.

One of the most important elements of the unsuccessful military bid was the high bypass turbofan engine selection. The competition pushed engine manufacturers to develop massive, fuel-efficient engines. Although the military chose General Electric, the technology enabled the creation of the first 747 powerplants. The Pratt & Whitney JT9D would provide the massive thrust needed for the world’s first jumbo jet.

The military requirement for ‘roll-on-roll-off’ (RO-RO) capabilities, or loading from the front and back, directly influenced Boeing’s decision to maintain a front-loading nose for the commercial 747. The 747 also inherited a military-grade philosophy of redundancy for survival, including four independent hydraulic systems and a triple-spar wing structure for extreme durability. Its super-duty design, including the landing gear, has made it famous as one of the smoothest aircraft to fly and land.

The military bid was for a high-wing aircraft to keep engines away from debris on dirt runways, whereas the civil-use 747 used a low-wing design for better efficiency and easier maintenance in commercial airports. Despite losing the military contract, Boeing’s bet on the cargo-focused design of the 747 allowed the Queen of the Skies to outlast supersonic competing designs of the era and remain a dominant force in global logistics for over 50 years.

How Long Will The Boeing 747 Remain Flying?

With deliveries of the jumbo jet having only ceased in recent years, the type looks set to continue flying for several decades to come.

The Finest 747 Freighters

The 747 equipped with a nose door from the factory is the most desirable of the freighter variants made by Boeing because of its high yield advantage for the Air Cargo industry. Because BCFs are too expensive to retrofit with a nose door, companies with factory-built freighters can charge a premium for transporting niche, ‘un-shippable’ cargo that no other commercial plane can handle.

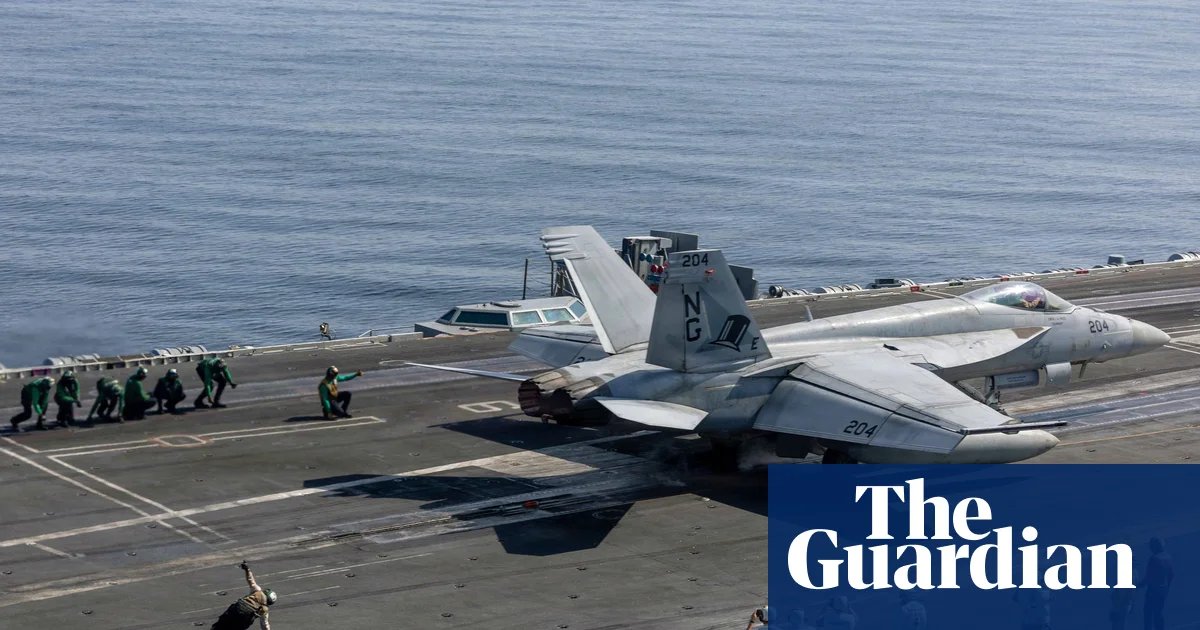

Special industrial cargo like heavy mining equipment, massive electrical generators, and large-scale manufacturing tools can only be carried by sliding directly onto the main deck of the 747’s with nose doors. For high-value vehicles, like luxury cars or even fighter jets, the nose door provides a direct path for driving or sliding the equipment straight onto the main deck. Many military assets, like helicopters and light armored vehicles, require the RO-RO feature of the nose door in order to be moved.

Atlas Air is still the largest operator in the world with over a 60-strong fleet of 747 jumbos. Atlas routinely transports massive engines and equipment, as well as industrial machinery and more, in support of the growing global e-commerce market. Cargolux Airlines, based in Luxembourg, is another all-cargo airline that operates 26 jumbos, including a large fleet of the advanced 747-8F, for which it was the launch customer. Kalitta Air is also a famed operator that routinely supports the US military with its large 747-400F fleet.

The Last Boeing 747-400 In America With A Passenger Cabin

Only one Boeing 747-400 in a passenger configuration still flies with Atlas Air.

Boeing’s Most Marvelous Door

To lift a door the size of a garage, while ensuring it stays airtight at 35,000 feet, the 747 uses a mix of brute force and precision engineering. The nose is a massive upward-swinging hatch powered by an electric motor and a dual-actuator screw jack system, as KHT Aviation explains. The door is attached to the fuselage via two massive upper-link hinges. When activated, the screw jacks push the nose upward and outward, clearing the floor for loading.

While most aircraft systems are hydraulic, the nose door uses an electrical system to ensure it can be opened even if the engines are off and hydraulic pressure is low at a remote airfield. Once the door is lowered, a series of 16 heavy-duty latch actuators engage. These hooks pull the door tight against the fuselage frame. The door is designed as a plug-type door, meaning the internal cabin pressure actually helps push the door into its frame.

The flight deck has a dedicated indicator panel that monitors every single latch. If even one hook isn’t perfectly engaged, the plane’s pressurization system will not allow the cabin to climb. In the event of a total electrical failure, the nose can be opened using a manual hand-crank system located near the door’s interior hinges. The hinge points are even fitted with structural shear pins designed to break under specific, extreme loads to prevent the door from ripping the entire front of the aircraft off in a catastrophic bird strike or ground collision.

Why In The World Does The Boeing Dreamlifter Fly To Miami?

Why does the largest Boeing jet ever made fly to Miami so much?

The Flipped Freighters

The 747-400LCF Dreamlifter is a fascinating departure from the standard 747 freighter. While the standard freighter uses a nose door to slide cargo in, the Dreamlifter uses a swing-tail because the cargo it was designed to carry is physically too large to fit through the nose of the airplane. The Dreamlifter was built for one specific purpose: transporting massive sections of the Boeing 787 Dreamliner.

These ‘Frankenstein’ aircraft were made as conversions by Evergreen Aviation Technologies (EGAT) in Taiwan to serve the 787 supply chain, but are flown by Atlas. The 787 fuselage is too big to even fit in the 747 with a nose door, so the Dreamlifters don’t have that at all and instead have an oversized fuselage bay with a rear hatch. They cut off the top of the original fuselage and replaced it with a massive, bulbous upper deck to increase the cargo volume.

The most complex part was the tail. By cutting the plane near the rear and installing a massive hinge, Boeing could open the entire diameter of the bulged fuselage. This allows the 787 sections to be slid in from the back, where there are no structural obstructions like the cockpit.